Die-sets standard parts

Guiding elements

The products meet the highest requirements for surface smoothness and shape tolerance, and their compliance with standards guarantees full interchangeability both between different types of guides and with the standards of other manufacturers.

Our offer includes:

- guide pillars in accordance with ISO 9182, DIN 9833, AFNOR

- steel bushes in accordance with ISO 9448

- bushes with bronze inserts in accordance with ISO 9448

- self-lubricating bushes in accordance with 9448, DIN 9834

- bushes with ferrite inserts in accordance with ISO 9448

- ball guides in accordance with ISO 9448

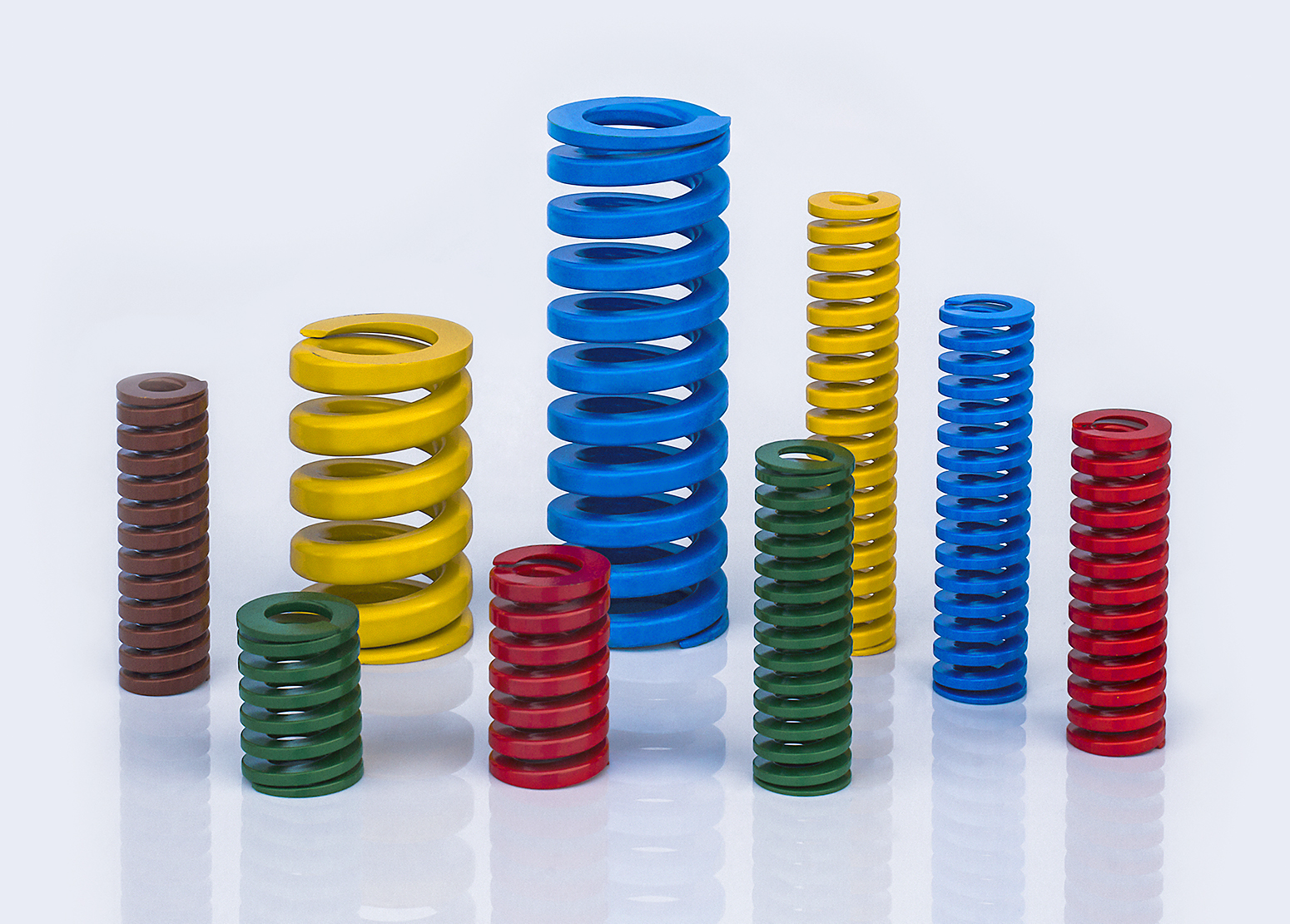

Springs

Manufactured by the Japanese company TOHATSU, the coil springs guarantee the highest load capacity while maintaining maximum spring life.

The range of products we offer includes:

- springs for stamping dies in accordance with ISO 10243

- springs for stamping dies in accordance with JIS B 5012

- round wire compression springs

- disc springs

Elastomer springs

An alternative to steel springs are springs made of polyurethane elastomer, available in diameters from Ø12 to Ø150 in several hardness groups: 70, 80, 90, and 95 Shore, as well as special plates and fittings.

Advantages of elastomer springs:

- ease of installation and replacement

- high wear resistance

- resistance to oils and greases

- transmission of heavy loads combined with small dimensions

- in case of failure they do not damage the tool

Gas springs

Founded in 1982, AZOLGAS is the first European manufacturer of gas springs for sheet metal forming tools. AZOLGAS gas springs are widely used in metal stamping, in injection moulding, in special machines, and in industrial automation.

Advantages of gas springs:

- force can be adjusted by changing the nitrogen pressure

- springs can work in a connected system

- high force transmission combined with small dimensions

- uniform increase in force depending on the spring stroke

- no need to use preload

- longer service life time counted in millions of working cycles

- not subject to the process of deposition and material fatigue

Sliding elements

Sliding elements are mainly used as guides in stamping, injection moulding, assembly jigs, and other mechanical engineering projects. A wide product range in terms of dimensions and types makes it possible to select standard solutions for almost every possible application.

Properties of sliding elements:

- maintenance-free

- abrasion-resistant

- low coefficient of friction

- max. operating temperature of about 200°C

- no harmful substances

- corrosion-resistant

- resistant to dynamic loads

Numbering stamps

Numbering stamps with interchangeable fonts complement our range of standardised products for stamping. They are commonly used in progressive and transfer stamping machines.

Additionally, we offer:

- stamps for embossing inscriptions, graphic signs, logos

- multi-function numbering stamps

- embossing stamps

- marking inserts and inserts holders according to customer requirements

- marking wheels

- electrodes

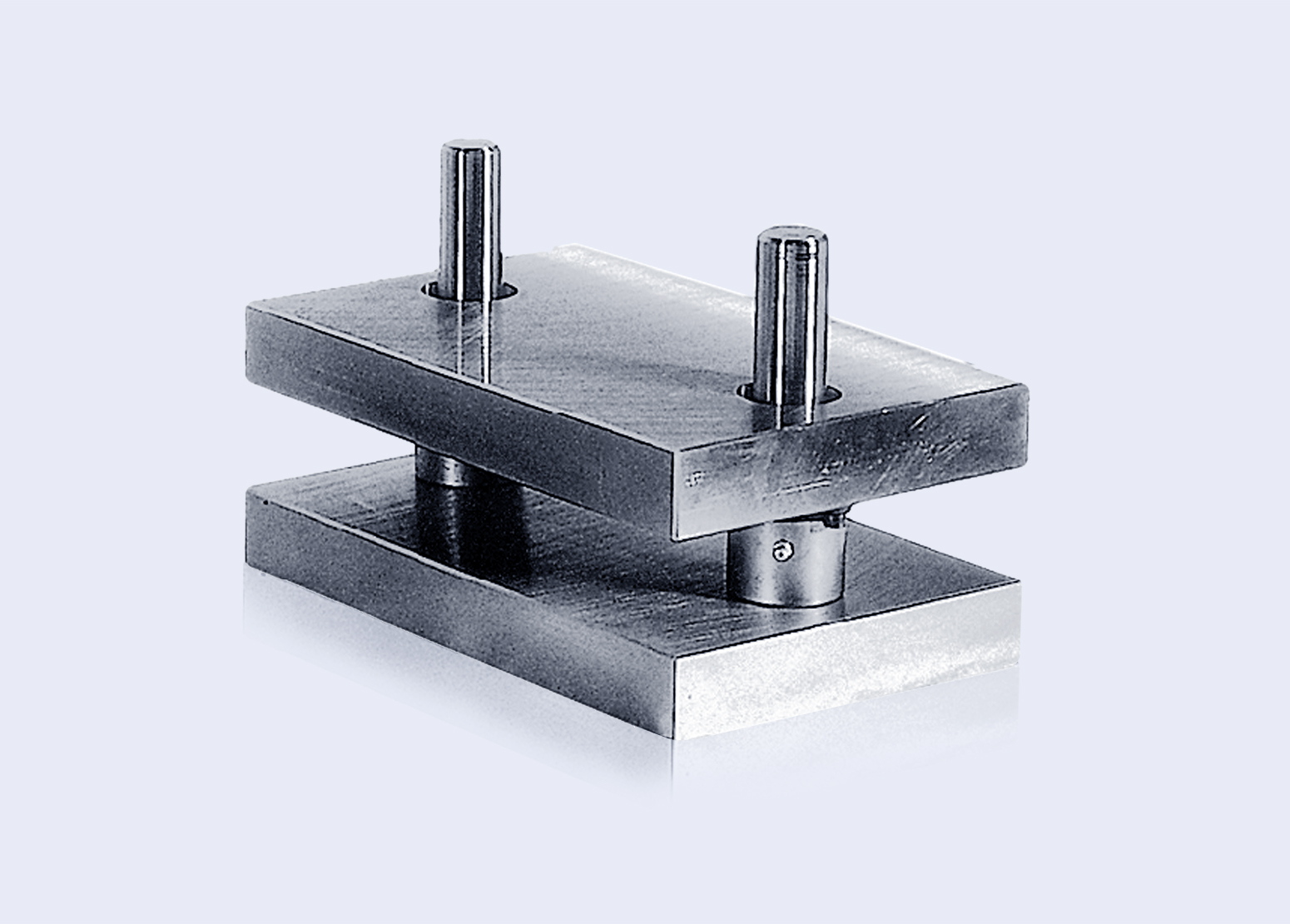

Die-sets

We supply high-quality standardised die-sets manufactured by the German company RSB Stahl. They are used in the production of various types of punched and stamped parts.

They are available in the following versions:

- 2-plates (without intermediate plate)

- 3-plates (with intermediate plate)

- size range from 250x160x32 mm to 710x630x63 mm.

The following standard guide elements can be used in die-sets:

- pillars without a flange or with a flange

- steel bushes, self-lubricating, with bronze insert or ball guides