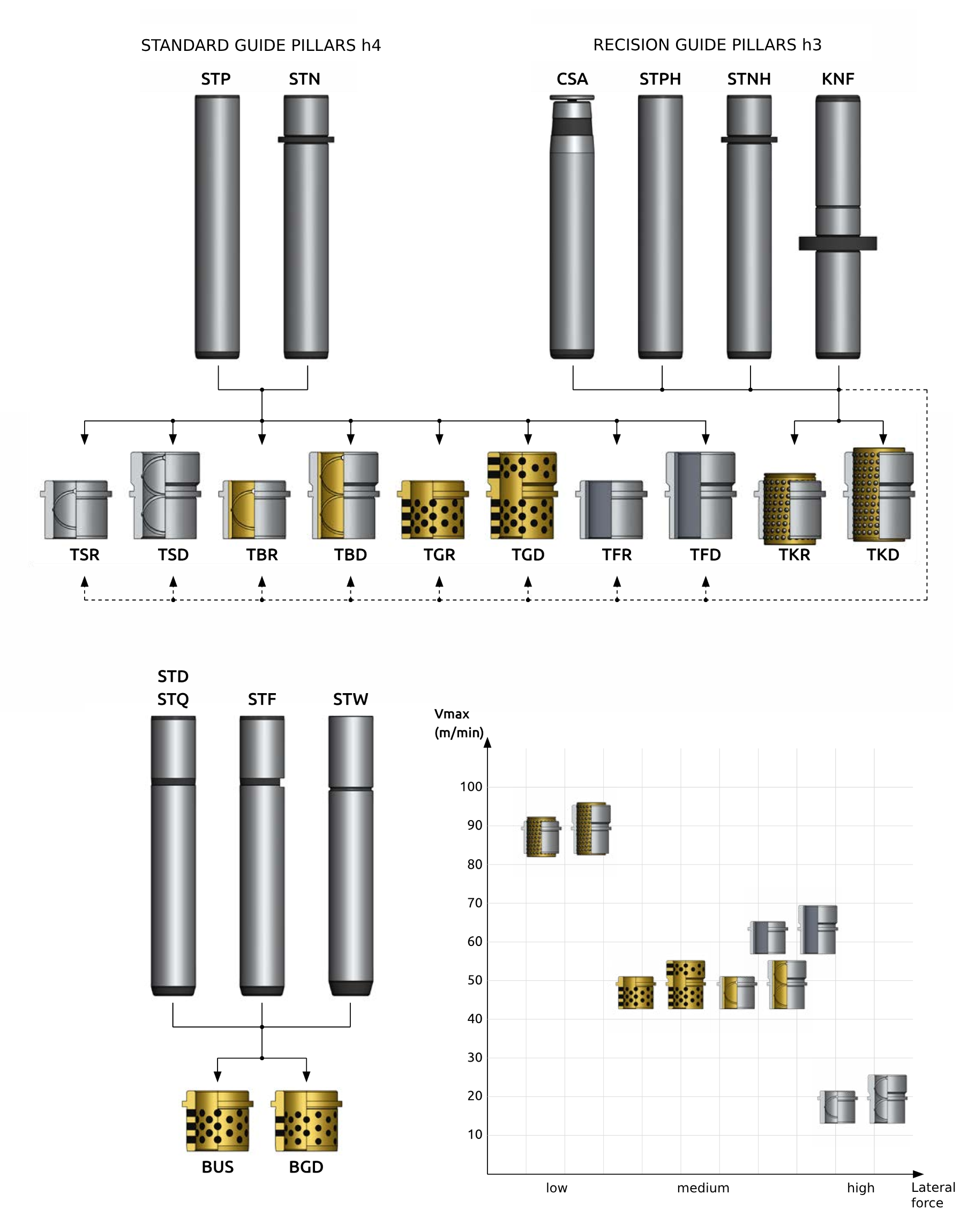

Selection of guides for stamping dies

TSR / TSD / TSK steel guide bushes

Steel guide bushes may be used wherever high forces and especially lateral forces appear. Due to high friction on contact surfaces, this type of guiding is recommended in applications where the speed does not exceed 20m/min. The bushes require constant lubrication. Grease or oil can be supplemented to the spiral grooves through a grease nipple located on the sleeve flange.

TBR / TBD / TBK / BEB guide bushes with bronze inserts

Guide bushes with bronze inserts are composed of an external steel sleeve with a centrifugally cast bronze insert. The insert has spiral grooves that ensure constant and even distribution of grease which can be supplemented through a grease nipple located on the sleeve flange. Thanks to the centrifugal casting process, the bronze layer is of such thickness that even in case of high wear the steel part does not come in contact with the guide pillar, preventing it from damage.

TGR / TGD / BUS / BGD self-lubricating guide bushes

Self-lubricating elements are used wherever excellent sliding properties and a long service life of the component are required. They work well both in rotary and in linear applications. The raw material used in self-lubricating parts is bronze or steel, which provide excellent mechanical properties, and graphite impregnated with a lubricant. During the initial work stages, due to friction with the contact surface, the lubricating agent releases gradually, creating a film which ensures slip in further cycles. Depending on the type of the element, the graphite contact (sliding) surface amounts to between 25% and 35% of the total working surface. Under the recommended operating conditions, the self-lubricating components do not require any maintenance.

TFR / TFD / BFD guide bushes with sintered ferrite insert

Precision guide bushes with sintered ferrite inserts are composed of an external steel sleeve with a sintered ferrite insert tightly pressed in. The insert has a sponge-like structure with surface porosity up to 20%. At the final production stage the pores are saturated with oil in vacuum chambers. Under the influence of temperature, the oil gradually flows out creating a friction-reducing film. Additional lubrication is possible only with recommended lubricants. Using grease other than recommended causes pore-clogging. Guide bushes with sintered ferrite inserts can be successfully used in high-speed tools and with extreme loads.

TKR / TKD / TKP / TKK ball bearing guides

Unlike in the other types, in ball bearing guides the sliding friction phenomenon does not exist. Movement resistance results mainly from rolling friction which is significantly smaller. Ball cages are made of a brass sleeve with balls firmly fitted in its cavities. Thanks to the appropriate guide and bush tolerances, a “preload” effect appears, eliminating any guiding clearance. Low friction and the lack of clearances allow the use of ball cages wherever high precision and extreme speeds are required.

| Bush type | Bush code | Recommended class of pillar precision | Type of guiding | Max. speed | Type of lubricant | Application |

| Steel with oil grooves | TSR, TSD, TSK | h4 | slide | 20 m/min | <12 m/min – grease | General purpose, die casting molds and for rubber, die-sets and injection moulds. Intended for short production series. |

| Steel with bronze insert | TBR, TBD, TBK, BEB | h4 | slide | 50 m/min | <30 m/min – grease >30 m/min – oil | Die-sets, injection moulds, machine parts.The most common guiding type. |

| Bronze with graphite inserts (self-lubricating) | TGR, TGD, BUS, BGD | h4 | slide | 50 m/min | <30 m/min – dry >30 m/min – oil or grease | Die-sets and injection moulds, general purpose machine parts. Applications with limited access to the sleeves (no regular lubrication). |

| Steel with sintered ferrite insert | TFR, TFD, BFD | h3 | slide | 60 m/min | <30 m/min – dry >30 m/min – oil | Machine parts exposed to extreme operating conditions. Die-set and punch guidings for large production volumes, applications with high speeds and with modern structural sheets. |

| Steel and ball bearing | TKP, TKR, TKD, TKK | h3 | roller | 60 m/min | oil or grease | Blanking dies and other tools with very high working speeds. Applications that require high precision. |