Punch and die sharpening

Punches and dies for punching holes are the elements of stamping dies that are the most susceptible to wear. With the correct selection of cutting elements, wear usually consists of blunting of the cutting edges, which negatively affects the quality of the punched hole and sometimes even the geometry of the manufactured details. In many cases, it turns out that sharpening of punches and dies is more profitable than replacing them.

Factors determining whether sharpening punches and dies is profitable

WEAR - If the punches or dies are in a relatively good condition (dull, slightly chipped)

PRICE - If the cost of sharpening is much lower than the cost of purchasing new punches or dies

TIME - If the production time for new punches or dies is unacceptably long

At our plant, in addition to the production of new elements, we also sharpen used parts. Please contact us to discuss details and obtain an individual quote.

The sharpening process:

.png)

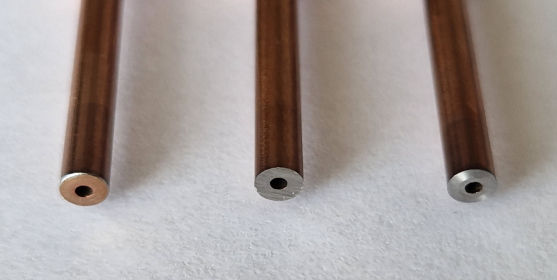

1. Visual assessment and measurement of possible deformations

2. Cleaning and removing the PVD coating, if necessary

3. Rough machining

4. Fine machining - grinding, EDM, polishing

.png)

5. Degreasing and re-applying the PVD coating

.png)

6. Final inspection and marking