Newstark

.png)

Newstark is a renowned manufacturer of high-quality components for stamping, with over two decades of experience. It specialises in providing innovative and highly efficient solutions for companies looking for high-tech components.

Thanks to its extensive technical know-how and optimised offer, Newstark offers the best solutions in terms of both performance and quality. The products are designed and manufactured with the highest precision, ensuring reliability and excellent results in stamping processes.

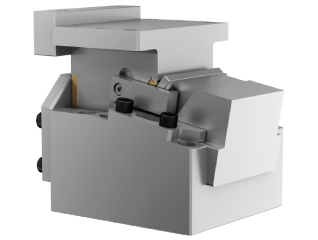

MAE cam units

This model represents the top of Newstark’s production range which incorporates unique and innovative solutions. The system fits an ISO 8020 standard direct integrated punch, easily available on the market. MAE cam units are characterized by large working strokes while maintaining compact dimensions. They are perfectly adapted to work in both horizontal and angled positions, which ensures their versatility and flexibility in various applications.

Technical properties

- Working force: 4500 - 30000 daN

- Angle: od -45° do 45° (5° step)

- Return by integrated gas spring (in case of its failure - mechanically)

- It is possible to install position sensor

- Application: cutting, pressing

MASE cam units

This model represents the top of Newstark’s production, range which incorporates market unique and innovative solutions. The system fits an ISO 8020 standard direct integrated punch, easily available on the market. MASE cam units are characterized by large working strokes while maintaining compact dimensions. They are perfectly adapted to work in both horizontal and angled positions, which ensures their versatility and flexibility in various applications.

Technical properties

- Working force: 4500 - 30000 daN

- Angle: from -15° to 15° (5° step)

- Return by integrated gas spring (in case of its failure - mechanically)

- It is possible to install a position sensor

- Application: cutting, pressing

.png)

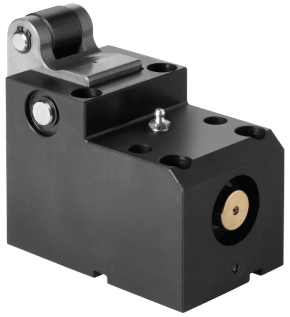

SMEG cam units

SMEG cam units are unique cutting units that have no equivalent on the market. They are equipped with cylindrical head punches in accordance with the ISO 8020 standard. Moreover, SMEG cam units are distinguished by a stripper made of aluminium bronze, and their drive uses a special, patented gas spring. This innovative design ensures not only high efficiency, but also precision and reliability in the punching process. SMEG cam units are therefore a perfect solution for customers who need an effective and reliable tool.

Technical properties

- Working force: 4500 - 10000 daN

- Angle: from 5° to 50° (5° step)

- Return by both coil springs and mechanically

- It is possible to install a position sensor

- Application: cutting, pressing

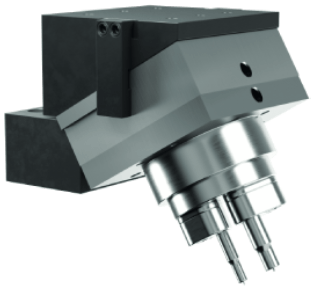

SUPER SMEG cam units

SUPER SMEG cam units are unique units that have no equivalent on the market. Their characteristic feature is a specially designed work surface that allows the installation of any accessories. Thanks to this, users can adjust the cam to their individual needs and applications. Flexibility and versatility make SUPER SMEG cam units extremely useful in various industries and production processes. Regardless of requirements and specifications, users can adapt SUPER SMEG cam units to their specific tasks, which contributes to increased efficiency and precision of work.

Technical properties

- Working force: 6000 - 60000 daN

- Angle: from 5° to 50° (5° step)

- Return by integrated gas spring

- It is possible to install a position sensor

- Application: shearing, drilling and pressing

M/ML cam units

M/ML cam units are small size units that have been specifically designed for punching holes. They are equipped with cylindrical head punches in accordance with the ISO 8020 standard. Due to their small size, M/ML cam units are practical to use and can be used in various applications where high punching precision is required.

Technical properties

- Working force: 1000 - 5000 daN.

- Angle: from -40° to 40° (5° step)

- Return by coil springs, and elastomer spring as stripper

- It is possible to install a position sensor

- Application: cutting, pressing

MA cam units

MA cam units are versatile units that are characterized by an innovative design based on unique solutions. The key element of these sliders is the moving part, which is protected against rotation. This design ensures the stability and precision of the cam operation. An additional advantage of MA cam units is the possibility to mount any accessories to the moving part. This gives users the freedom to adjust the cams to suit different tasks and requirements.

Technical properties

- Working force: 2500 - 10000 daN.

- Angle: from -45° to 45° (5° step)

- Return by integrated gas spring (in case of its failure - mechanically)

- It is possible to install a position sensor

- Application: shearing, drilling and bending

MAS cam units

MAS cam units are versatile units that are characterized by an innovative design based on unique solutions. Similarly to MA cam units, MAS cam units have a moving part that is protected against rotation, ensuring stability and precision of operation. The advantage of MAS cam units is the possibility to mount any accessories to the moving part. This gives users the freedom to adjust the cams to suit different tasks and requirements.

Technical properties

- Working force: 3000 - 19000 daN.

- Angle: from -30° to 30° (5° step)

- Return by integrated gas spring

- It is possible to install a position sensor

- Application: shearing, drilling and bending

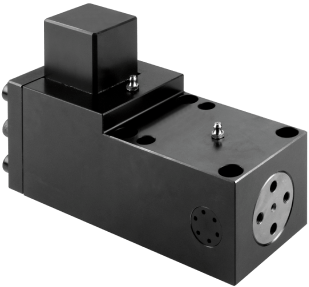

MASC cam units

MASC cam units are versatile units that are distinguished by an innovative design based on unique solutions. One of the characteristic features of MASC cam units is a rectangular or square movable part that allows the installation of any accessories. Thanks to this design, users have the ability to adapt the cam units to various tasks and requirements by selecting and installing appropriate accessories. The solid design of the MASC cam units ensures stability and high precision of operation even in difficult tool construction applications.

Technical properties

- Working force: 8000 - 40000 daN

- Angle: from -30° to 30° (5° step)

- Return by two integrated gas springs

- It is possible to install a position sensor

- Application: shearing, drilling and bending

.png)

MASC COMPACT cam units

MASC COMPACT cam units are versatile units that are distinguished by an innovative design based on unique solutions. Similarly to MASC cam units, MASC COMPACT cam units have a rectangular or square movable part, allowing the installation of any accessories. The MASC COMPACT model is a more compact version of the MASC cam units that has been optimized for compact dimensions. Despite their compact design, MASC COMPACT cam units remain versatile and flexible in use. Thanks to unique design solutions, MASC COMPACT cam units are reliable tools that enable precise and effective performance of various operations. Their compact size makes them ideal for applications where space is limited but versatility and high quality of work are required.

Technical properties

- Working force: 8000 - 40000 daN

- Angle: from -30° to 30° (5° step)

- Return by two integrated gas springs

- It is possible to install a position sensor

- Application: shearing, drilling and bending

ROLLER cam units

ROLLER cam units are versatile roller-driven units that are distinguished by an innovative design based on unique solutions. They are characterized by a large working surface, which allows the installation of any accessories, providing the user with great flexibility and the ability to adapt to various tasks. ROLLER cam units are designed to provide large working strokes. This allows users to perform precise and efficient operations on various materials and in various applications. The working strokes of the ROLLER cam units allow you to make deeper holes or cut larger surfaces, which increases their versatility and use. The design based on a roller drive guarantees smooth and precise cam guidance, ensuring high quality and accuracy of performed operations. ROLLER cam units are reliable and efficient, enabling users to achieve excellent results.

Technical properties

- Working force: 3400 - 25800 daN

- Angle: from -50° to 15° (5° step)

- Return by integrated gas spring (in case of its failure - mechanically)

- It is possible to install a position sensor

- Application: shearing, drilling and bending

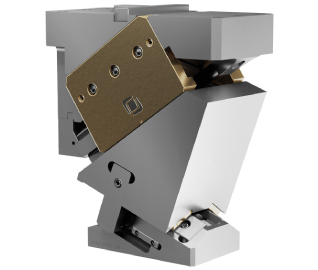

AERIAL cam units

AERIAL cam units are wedge-driven units whose working part is attached to the upper half of the tool. They allow you to perform operations such as cutting, punching, bending, embossing both horizontally and at an angle ranging from 0° to 75°. Thanks to the materials used and the appropriate design, they are suitable for places where high strength is required. Return is achieved by gas springs.

Technical properties

- Working force: 9200 - 120200 daN

- Angle: from 0° to 75° (5° step)

- Return by integrated gas spring

- It is possible to install a position sensor

- Application: shearing, drilling and bending

DIE MOUNTED cam units

DIE MOUNTED cam units are wedge-driven units whose working part is attached to the lower half of the tool. They allow you to perform operations such as cutting, punching, bending both horizontally and at an angle ranging from 0° to 20°. Return is achieved by gas springs or coil springs, depending on the model.

Technical properties

- Working force: 3800 - 48000 daN

- Angle: from 0° to 20° (5° step)

- Return by integrated gas spring

- Application: shearing, drilling and bending

Newstark products catalog

Choose the right product and check the technical parameters in the catalog.

| Download Newstark catalog | |

| Download AERIAL and DIE MOUNTED cam units catalog |

Online store and CAD files

Check the availability and prices of ER-EL products in our online store.

| Go to the B2B store | |

| Download CAD files |

Videos

Suwak MAE

Suwak MAE

Suwak SMEG

Suwak MASC