Gas spring protection systems

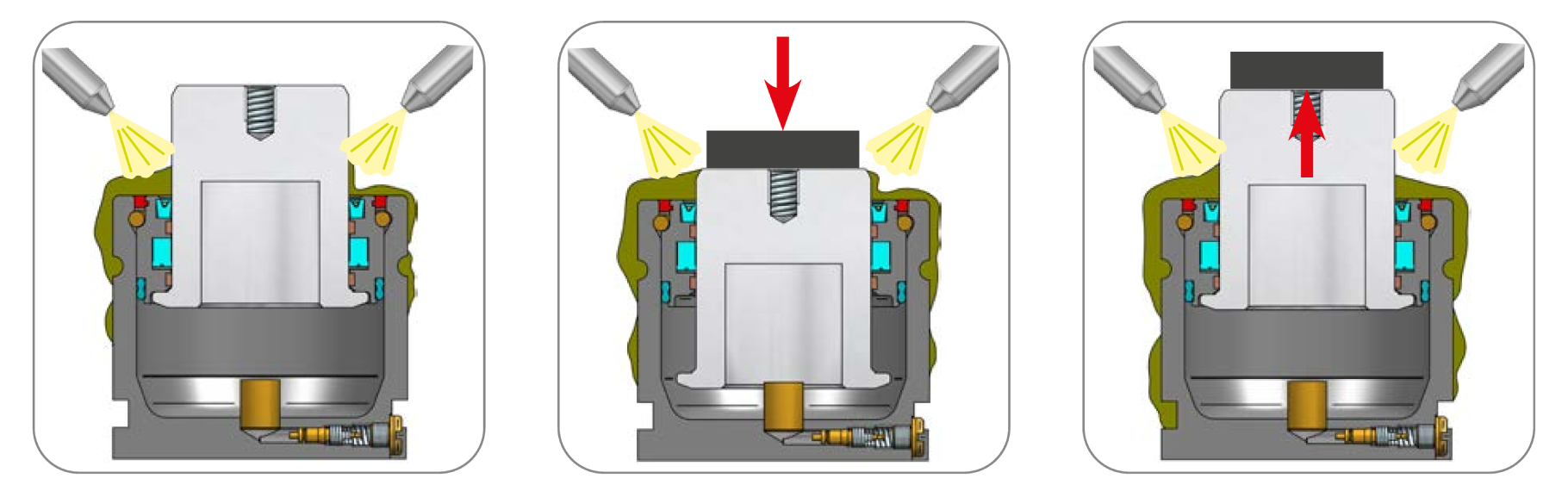

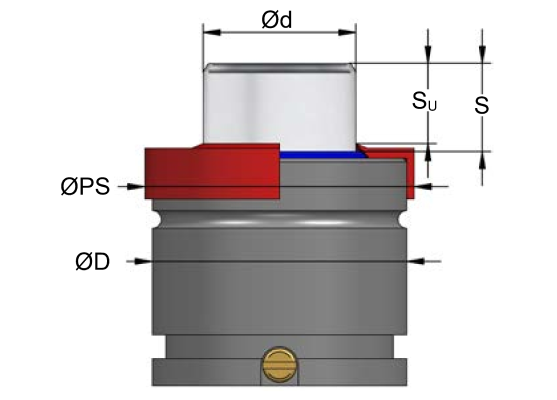

PS - PROTECTIVE SCRAPER

CHALLENGE

Certain application conditions involve the presence of liquid or solid contaminants. The amount of solid or liquid particles and prolonged operation cause the scraper the gas spring is equipped with to not protect the spring sufficiently in those conditions. The solid or liquid pollution introduced into gas springs causes the pressure and temperature to increase, which results in gas leaks and reduces their service life.

SOLUTION

Azolgas designed a PS protective scraper that fits both the body and the piston rod of the gas spring, minimising the impact of solid or liquid contaminants and extending the service life of gas springs. The PS protective scraper provides double protection, and it is particularly suitable for medium risk (solid and liquid particles without corrosive or piston-damaging factors). The PS protective scraper saves costs, it is easy to assemble by the user, it can be used with all types of flanges, and it causes minimal loss of the available stroke.

ADVANTAGES

- Easy to assemble

- Saves costs

- Compatible with all types of flanges

- Minimal loss of available stroke

- Extra protection against medium risks

TECHNICAL IINFORMATION

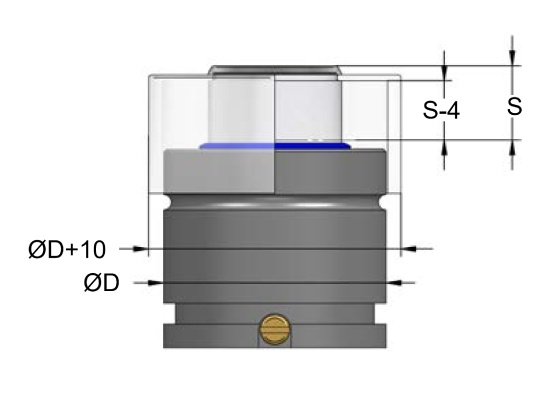

The use of the PS protective scraper causes a change in some of the dimensions of the gas spring. The body diameter ØD increases to the size of the diameter of the protective scraper ØPS. The nominal stroke S decreases to the size of the available stroke Su.

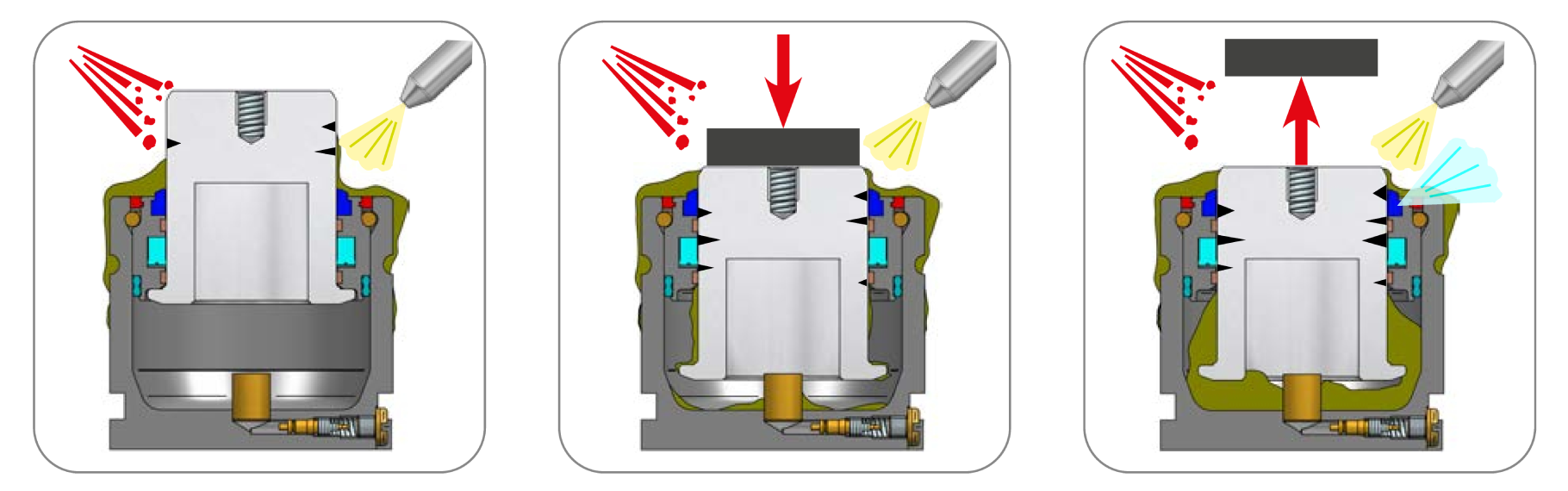

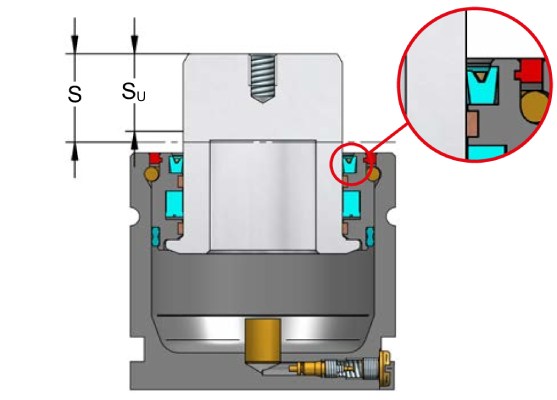

PV - ACTIVE SEAL

CHALLENGE

Certain application conditions involve the presence of liquid or solid contaminants. The amount of solid or liquid particles andprolonged operation cause the scraper gas springs are equipped with to not protect them sufficiently in those conditions. The solid or liquid pollution introduced into gas springs causes the pressure and temperature to increase, which results in gas leaks and reduces gas springs service life.

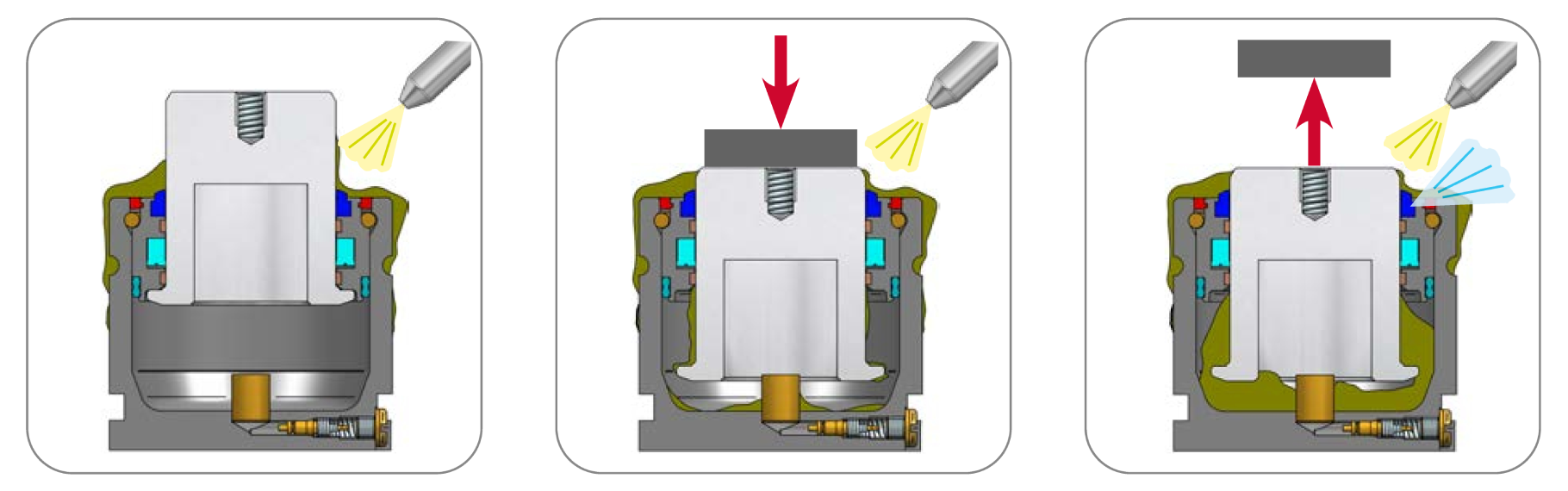

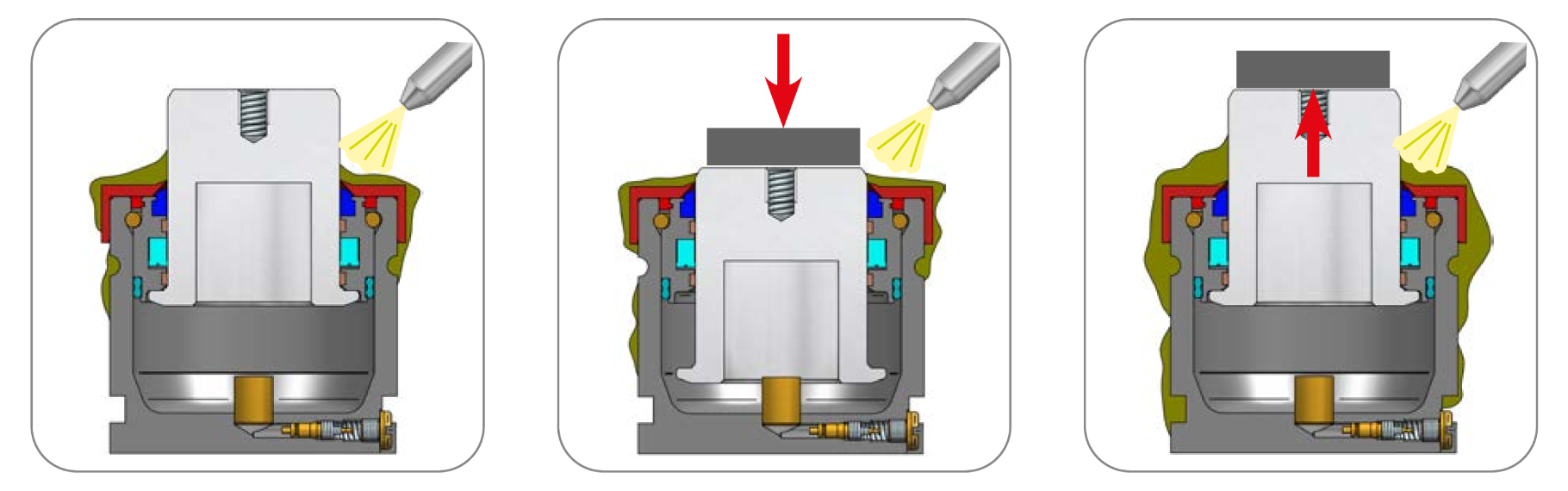

SOLUTION

AzolGas designed a protective PV system which provides an active seal minimising the impact of solid or liquid contaminants and extending the service life of gas springs. The PV protective active seal provides double protection, and it is particularly suitable for high risk (significant solid and liquid particles without corrosive or piston-damaging factors). The PV protective active seal saves costs, increases productivity, can be used with all types of flanges and in existing applications.

ADVANTAGES

- Saves costs

- Increases productivity

- Compatible with all type of flanges

- Use in existing applications

- Extra protection against high risks

TechniCaL INFORMATION

The use of the PV protective active seal does not cause a change in the dimensions of the gas spring. The protective active seal minimising the impact of solid and fluid contaminants is to be inserted into the gas spring.

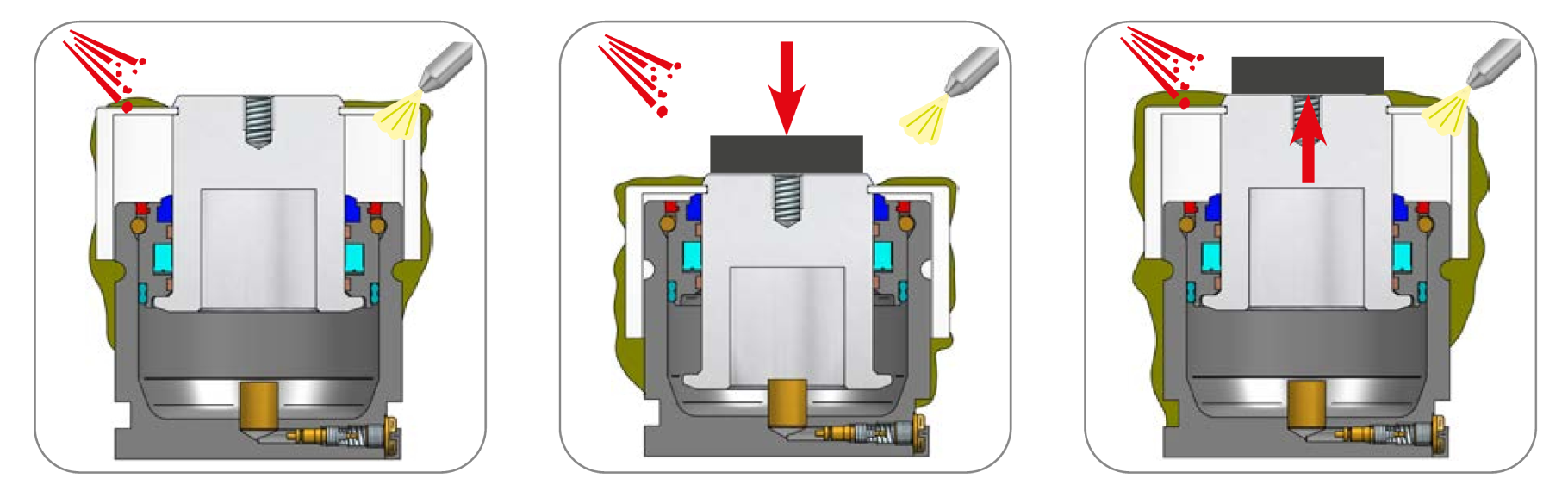

PC - PROTECTIVE COVER

CHALLENGE

Certain application conditions involve the presence of liquid or solid contaminants. The amount of solid or liquid particles and prolonged operation cause the scraper gas springs are equipped with to not protect them sufficiently in those conditions. The solid or liquid pollution introduced into gas springs causes the pressure and temperature to increase, which results in gas leaks and reduces gas springs service life.

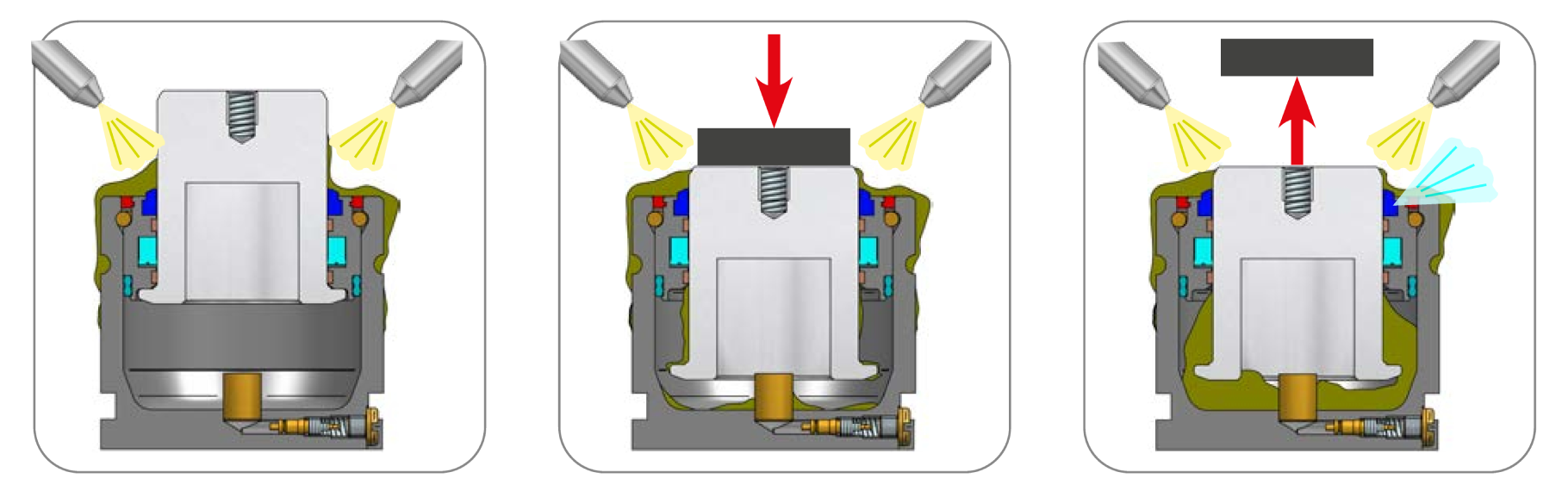

SOLUTION

Azolgas designed a protective PC cover hat fits both the body and the piston rod of the gas spring, minimising the impact of solid or liquid contaminants and extending the service life of gas springs. The PC protective cover provides double protection, and it is particularly suitable for high risks (significant solid and liquid particles without corrosive factors but capable of damaging the piston). The PC protective cover saves costs, increases productivity, it is easy to assemble by the user, and it causes minimal loss of the available stroke.

ADVANTAGES

- Easy to assemble

- Saves costs

- Increases productivity

- Minimal loss of available stroke

- Extra protection against medium risks

TECHNICAL INFORMATION

The use of the PC cover couses the body diameter ØD to increase to the diameter of the PC protective cover, and the nominal stroke S decrease to the size of the available stroke Cu. Notify Azolgas if the gas spring is to be installed upside down.