OMCR

_1.png)

OMCR

Over the last 15 years of its business, OMCR has gained a great deal of experience in both the design and manufacture of cam units used in stamping and punching machines. The presented range of sliders with a wide range of types, sizes, and transmitted forces will certainly cover most of your technological applications.

STAR CAM

| The Star Cam series of cam units (CHD, CHV, CLB, CRX, DHC) combine high performance, competitive price, and easy service. Thanks to the full availability of components for their construction, both cam units and spare parts are delivered in a short time. |

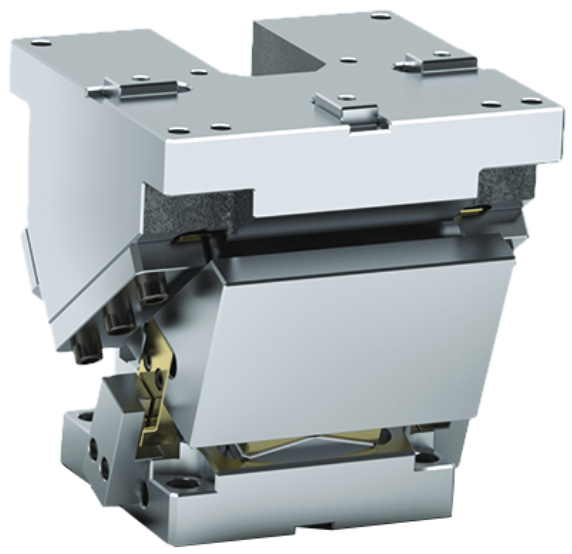

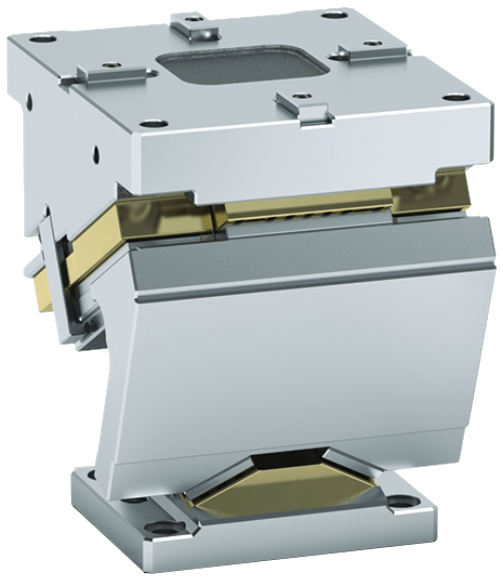

CHD aerial cam units

Strong and reliable, the CHD cam units are suggested for heavy-duty applications. Thanks to its solid construction and easy maintenance, it is perfect for high-volume production.

Technical properties

- Work surface: 50 – 300 mm

- Work force: 6000 – 655000 daN

- Angle: 0° – 65° (5° step)

- It is possible to choose between coil spring and gas spring return

- Sliding elements made of bronze with graphite inserts

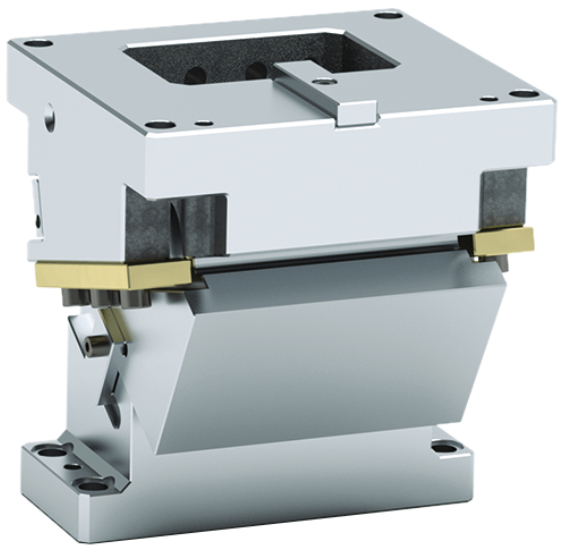

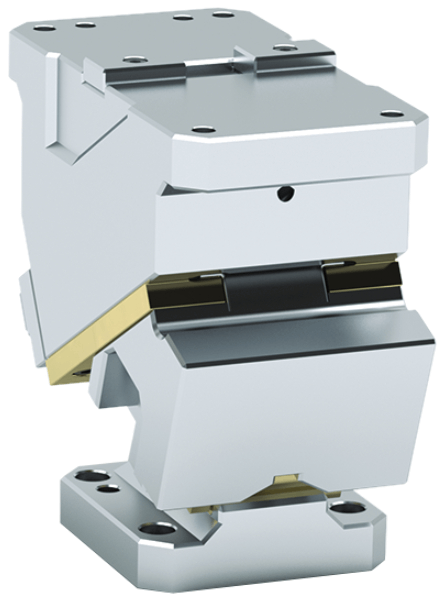

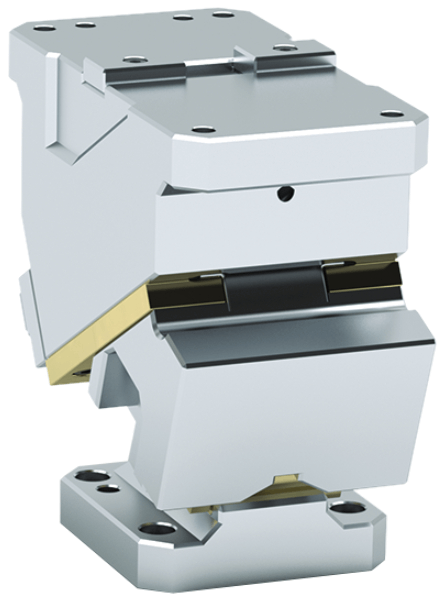

CHV aerial cam units

The CHV models represent the TOP of the whole range of OMCR’s cam units. They are compact in size, and have high work and extraction forces. They are built with high-strength materials which ensure excellent resistance to unbalanced loads and very good punching precision. They are characterised by easy maintainability thanks to the use of normalised wear plates (VDI3357) and to the possibility of gas spring demounting under press.

Technical properties

- Work surface: 50 – 600 mm

- Work force: 9200 – 120200 daN

- Angle: 0° – 75° (5° step)

- Gas spring return only (replacement without disassembling cam units)

- Easy maintenance due to the use of standardised sliding plates (VDI3357)

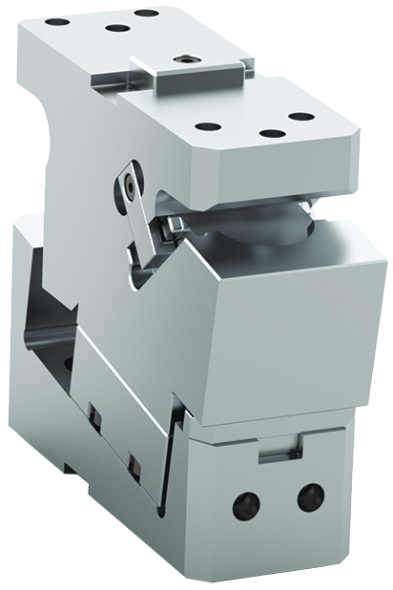

CHW aerial cam units

The CHW cam units are extremely compact and suitable for applications requiring high work forces. They are equipped with sintered steel sliding elements (SINT300®) and thanks to the new stop system, the cam slider can be easily disassembled for quick maintenance.

Technical properties

- Work surface: 65 – 110 mm

- Work force: 21000 – 32000 daN

- Angle: 0° – 75° (5° step)

- Sintered steel sliding elements (SINT300®)

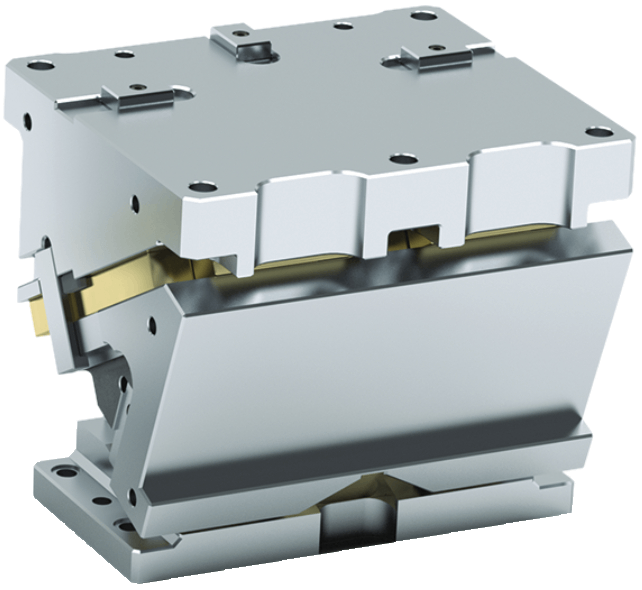

CLB aerial cam units

Strong and compact, the CLB cam units offer a very competitive price/performance ratio.

Technical properties

- Work surface: 200 – 600 mm

- Work force: 30200 – 86500 daN

- Angle: 0° – 60° (5° step)

- It is possible to choose between coil spring and gas spring return

CHK aerial cam units

The CHK cam units are suited for medium-light drilling and flanging operations. Thanks to use of a V guide on the driver, the cam units have improved alignment precision.

Technical properties

- Work surface: 65 – 200 mm

- Work force: 5800 – 23100 daN

- Angle: 0° – 70° (5° step)

- Coil spring return only

CHR aerial cam units

The CHR cam units are suited for heavy drilling and flanging operations. Manufactured according to NAAMS standards, these cam units are equipped with a cam accelerator to soften the noise level starting from width 165 mm.

Technical properties

- Work surface: 70 – 400 mm

- Work force: 9000 – 52100 daN

- Angle: 0° – 60° (5° step)

- It is possible to choose between coil spring and gas spring return

CLC aerial cam units

The CLC cam units are best suited for medium/light drilling and flanging.

Technical properties

- Work surface: 50 – 150 mm

- Work force: 4100 – 14000 daN

- Angle: 0° – 70° (5° step)

- Coil spring return only

CLD aerial cam units

The CLD aerial cam units are extremely compact and suited for medium-light drilling operations. They are not well suited for flanging operations.

Technical properties

- Work surface: 52 mm

- Work force: 3100 daN

- Angle: 0° – 80° (5° step)

- Coil spring return only

CLF aerial cam units

The CLF aerial cam units are suited for medium-light drilling and flanging operations.

Technical properties

- Work surface: 80 – 150 mm

- Work force: 11600 – 19200 daN

- Angle: 0° – 70° (5° step)

- Coil spring return only

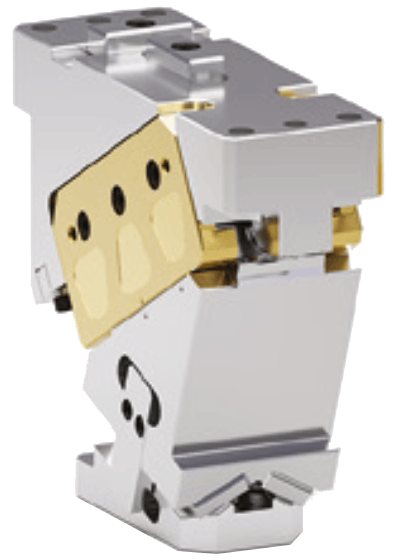

CRX roller cam units

Thanks to their compact size, the CRX cam units are particularly suited for making close punchings. Ease of mounting and flexibility in applications are their strong points. Optionally available with the possibility of emergency return. It is also possible to use a position sensor.

Technical properties

- Work surface: 78 – 240 mm

- Work force: 4500 – 25800 daN

- Angle: -15° – 50° (5° step)

- Gas spring return only

- It is possible to install position sensor

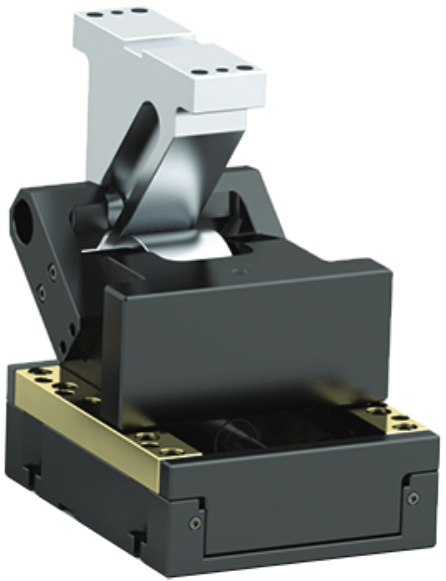

DHC die mounted cam units

The DHC cam units are suited for heavy drilling and flanging operations thanks to their construction in spheroid cast iron. They are characterised by easy maintainability thanks to the use of self-lubricating wear plates and steel elements on the most stressed slidings.

Technical properties

- Work surface: 52 – 400 mm

- Work force: 3800 - 48000 daN

- Angle: 0° – 20° (5° step)

- Gas spring return only

DLD die mounted cam units

The DLD die mounted cam units are suited for medium-light drilling. They are not suited for flanging operations.

Technical properties

- Work surface: 52 – 90 mm

- Work force: 4000 - 7900 daN

- Angle: 0° – 20° (5° step)

- Coil spring return only

Cam search

Using the search engine on the website www.omcr.it you can select a cam unit and obtain information about its parameters.

Download CAD files

From the website www.omcr.it you can download 3D CAD files (STEP, CATIA V5) of all standard cam units offered by OMCR.