Quality

Quality – is one of the pillars of our activity. We strive to maintain a stable, high quality of products through constant monitoring of processes and procedures in our company.

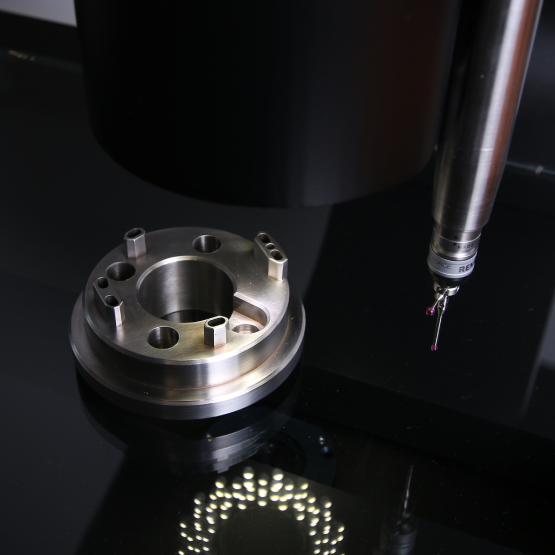

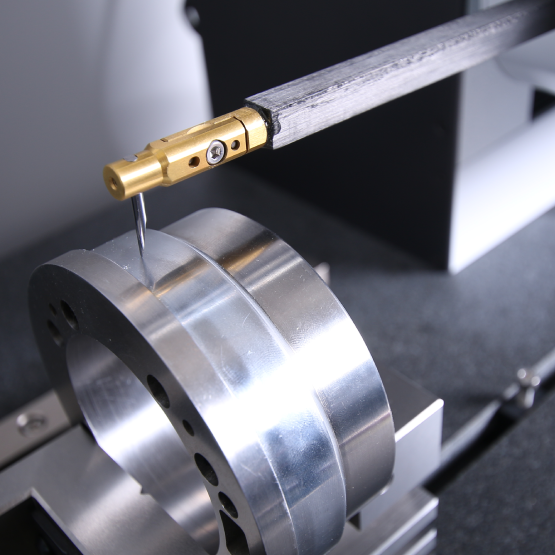

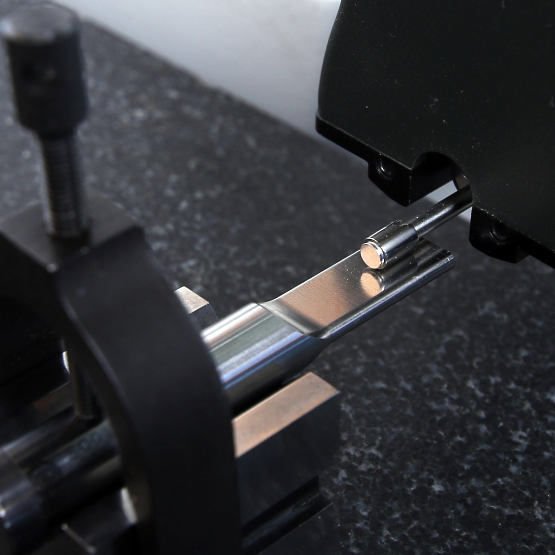

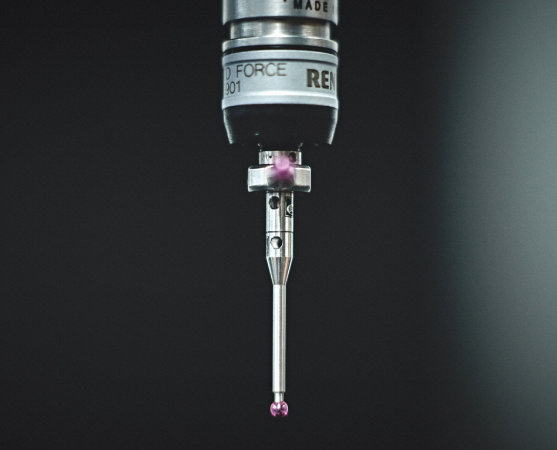

Parts are manufactured on the latest numerically controlled machines with rigorous inter-operational control. Each production batch undergoes thorough measurements in the Quality Department before being placed in the warehouse. All this, thanks to equipping our measuring room with modern, specialised devices for vision and contact inspection:

- pneumatic bore gauges for checking pillars and bushes,

- Venture optical - contact coordinate-measuring machine,

- station for measuring curves, profiles, and roughness,

- instruments for measuring concentricity and runout,

- Rockwell, Vickers, and Brinell hardness testers,

- Mahr roughness gauge.

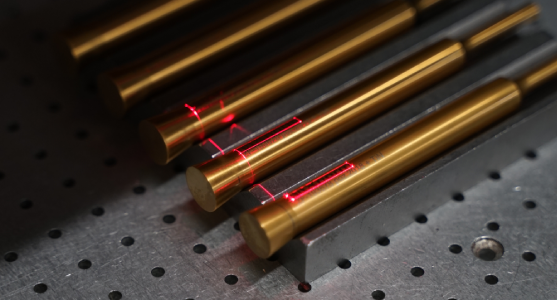

Laser marking of the production lot number has become the standard for most parts, enabling reverse analysis of the entire process. At the customer's request, we provide measurement cards and material certificates.

Special parts according to customer documentation make up a significant proportion of orders. The technical department provides assistance in optimising tool design, material selection, changes in dimensional tolerances, development of heat treatment technology, and the use of PVD and DLC coatings.

ISO 9001:2015 certificate

The possession of the ISO 9001 quality management certificate is the confirmation of operating at the highest level and meeting all requirements related to ensuring the quality and safety of products and services.

On 22 November 2022, our company once again obtained the ISO 9001:2015 Quality Management System certificate in the field of:

- distribution of standard parts for die sets and injection moulds,

- design and sales of systems and components for mechanisation of transfer presses,

- manufacturing of punches, dies and other precision parts for toolmakers.

The certification audit was conducted by the TÜV NORD POLSKA certification body.