Voestalpine

Voestalpine Camtec GmbH is a renowned international supplier of maintenance-free, self-lubricating sliding elements, whose products are mainly used in automotive stamping dies, tools and machines for plastics processing, as well as in other industries. The cam units we offer are extremely versatile and can be used in punching, shearing, and sheet metal shaping processes. Close cooperation with our clients has helped us develop an innovative generation of cam units that meet all their requirements. Our cam units are characterised by a compact design, which makes them extremely practical in installation and use. Additionally, they are designed to carry very heavy loads, ensuring reliability and durability in a variety of applications. Our goal is to provide solutions that contribute to the optimisation of production processes and increased operational efficiency of our clients.

Voestalpine Camtec GmbH is a renowned international supplier of maintenance-free, self-lubricating sliding elements, whose products are mainly used in automotive stamping dies, tools and machines for plastics processing, as well as in other industries. The cam units we offer are extremely versatile and can be used in punching, shearing, and sheet metal shaping processes. Close cooperation with our clients has helped us develop an innovative generation of cam units that meet all their requirements. Our cam units are characterised by a compact design, which makes them extremely practical in installation and use. Additionally, they are designed to carry very heavy loads, ensuring reliability and durability in a variety of applications. Our goal is to provide solutions that contribute to the optimisation of production processes and increased operational efficiency of our clients.

Advantages of cam units:

- optimum fit thanks to maintenance-free sliding elements

- hardened and ground surfaces

- long service life due to minimal wear and abrasion

- precise guidance

- high absorption of lateral forces

- adjustable clearance

- adjustable and removable gas spring

- all components available as spare parts

- compliance with the NAAMS standard

- patented drive system

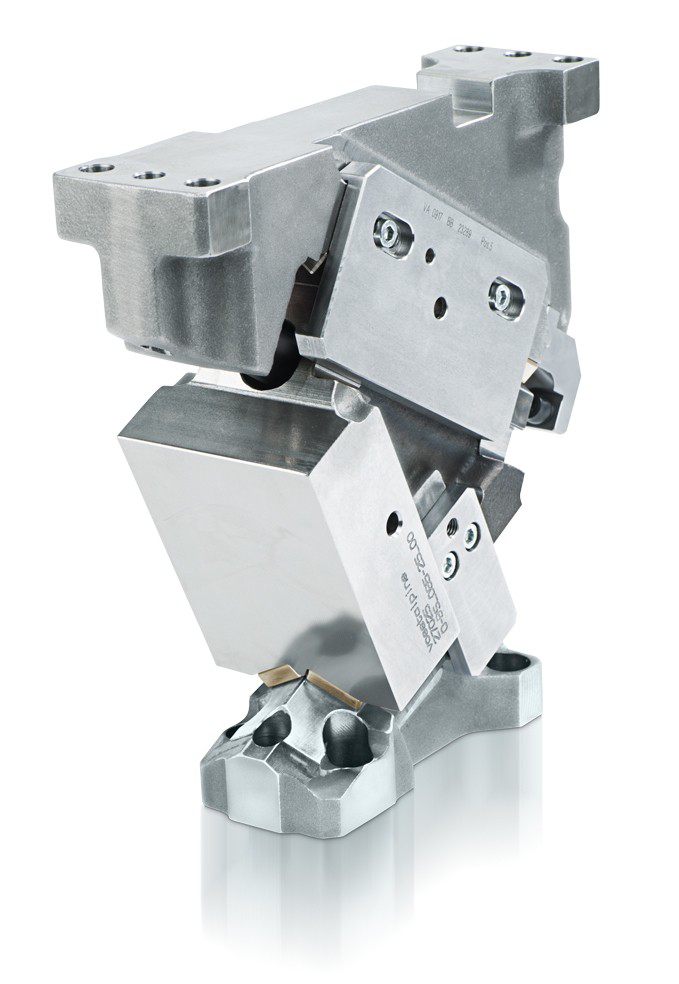

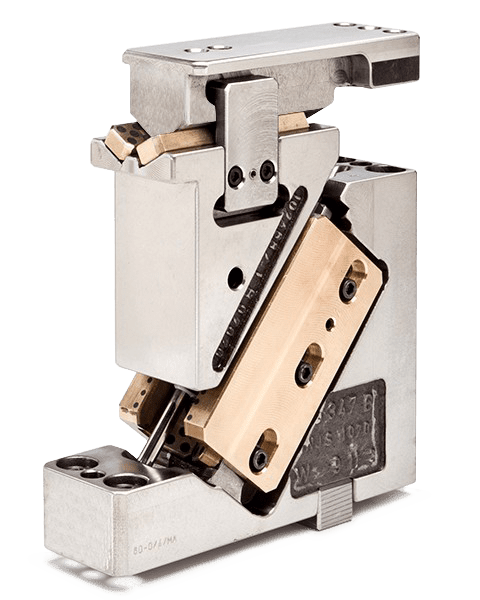

O-KS - optimised, new generation compact cam units

Forming, flanging, piercing, trimming — cam sizes and force requirements are important and critical factors in the stamping process. As a solution voestalpine Camtec developed a new cam generation which takes us to the next level. The result is the O-KS (optimised compact cam unit). Our latest achievement will prove its superiority with its compact but simple design, easy handling, and high retraction forces.

Dimensions

- Work surface: 60–500 mm

- Angle: 0–75° (5° step)

Technical properties

- Average service life: 2 million strokes

- Guaranteed service life: 1 million strokes

- Delivered assembled

- Sinter side plates

- Hardened sliding surfaces

- Complliant with BAK, VDI and NAAMS

- Special cam unit options

- At least 700 N/mm² tensile strength of driver, sliding element and cam bed materials

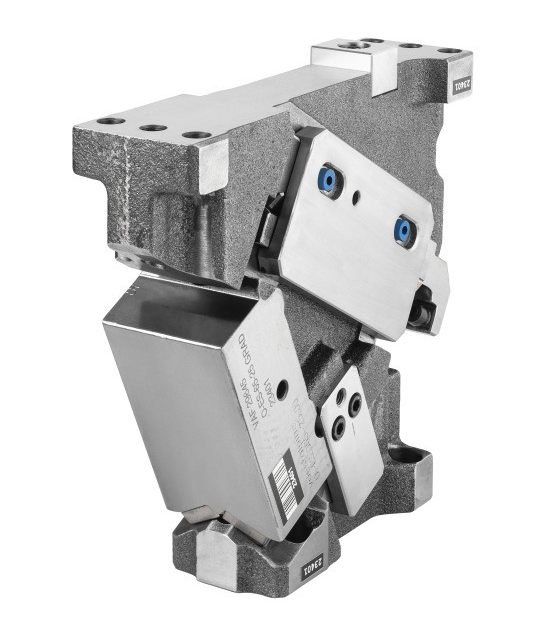

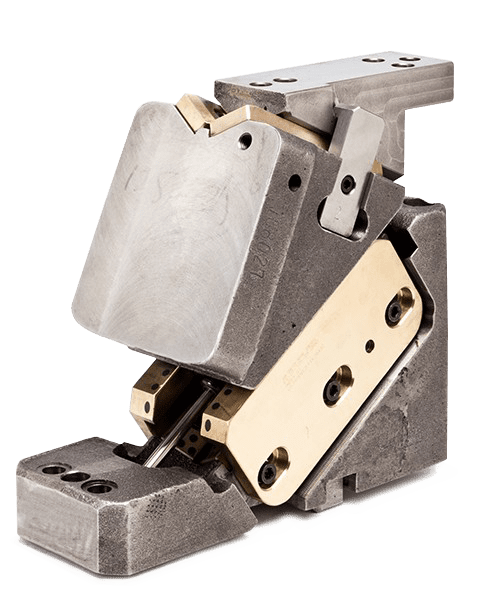

O-BS - optimised, new generation basic cam units

Our newly developed basic cam is an economical alternative to our premium series. With a load-dependent service life of up to one million strokes, it impresses with its optimised application options, simplified handling, and strong forces. Like all voestalpine Camtec cam units, our optimised basic cam is well-designed and consists of only a few components. This significantly simplifies spare parts management and the exchange of individual parts. Thanks to the side plates with double prism, the cam enables maximum precision in the smallest installation space. The side plates can even be easily readjusted in the press. The O-BS can be removed to the rear and to the side, thus ensuring efficient use in the tool and extremely simple maintenance.

Dimensions

- Work surface: 60 – 500 mm*

- Angle: 0 – 75° (5° step)

Technical properties

- Average service life: 1 million strokes

- Guaranteed service life: 500 000 / 750 000 strokes

- Delivered assembled

- Sinter side plates

- Compliant with BAK, VDI

- NAAMs insertion point

- Special cam unit options

- At least 600 N/mm² driver tensile strength, sliding element and cam bed materials

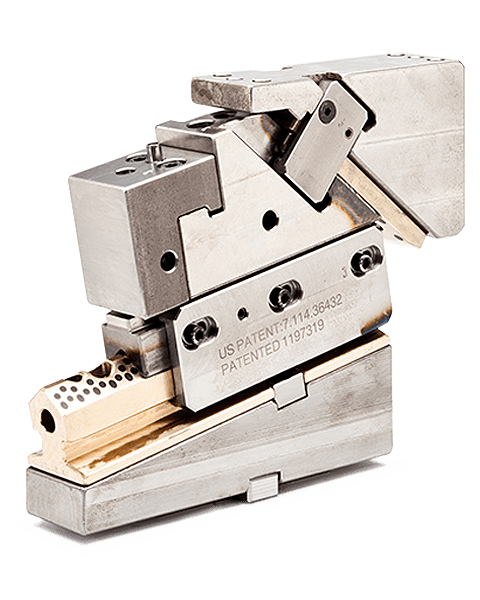

O-ES - optimised, new-generation elementary cam units

The new O-ES cam unit series is based on the tried and tested voestalpine design. Double prism drive plus side plates that were designed for price-sensitive industries and clients. As usual, O-ES is equipped with strong gas springs to provide you with high retraction forces. Fewer parts mean less complexity without impacting service life.

Dimensions

- Work surface: 50 – 500 mm

- Angle: 0 – 75° (5° step)

Technical properties

- Average service life: 1 million strokes

- Guaranteed service life: 300 000 strokes

- Casting material min. EN-GJS-400-15

- Retracting force similar to O-KS series

- Working force approx. 30% of O-KS

- Driver lock

- Can be removed to the rear

- Simple processing possible

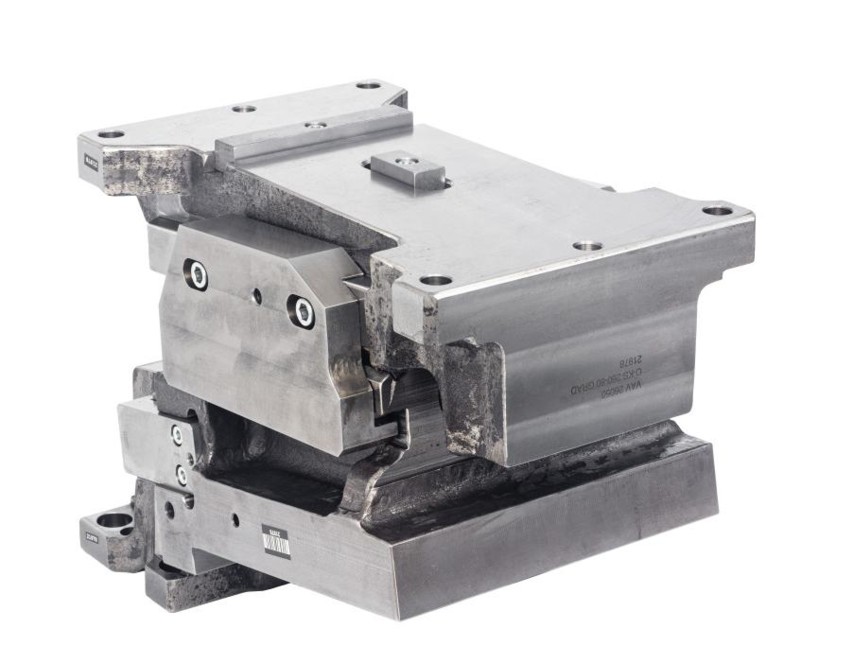

KS-OT / HS-UT - premium cam units

Premium-quality cams engineered and designed for high force levels and long-lasting performance. Available as aerial cam unit (KS-OT) and die mount cam unit (HS-UT).

Dimensions

- Work surface: KS-OT: 60-1600 mm / HS-UT: 50-1600 mm

- Angle: KS-OT: 0 - 75° (5° step) / HS-UT: 0 - 20° (5° step)

Technical properties

- Average service life: 2 million strokes

- Guaranteed service life: 1 million strokes

- Average specific load (width-dependent): 2,3 kN/mm

- Cast material at least GJS700-2

- Hardened sliding surfaces

- Increased retraction power possible

- Compliant with BAK, VDI and NAAMS

- Customization possible upon request

BS-OT / BS-UT - basic cam units

The optimum solution for tools with a medium number of units.

Dimensions

- Work surface: OT: 60 - 500 mm / UT: 50 - 500 mm

- Angle: OT: 0 - 75° (5° step) / UT: 0 - 20° (5° step)

Technical properties

- Average service life: 1 million strokes

- Guaranteed service life: 500 000 / 750 000 strokes

- Average specific load: 1,6 / 1,3 kN/mm

- Cast material at least GJS600-3

- Lockout system

- Increased retraction power possible

- Compliant with NAAMS

- Customisation possible on request

ES-OT - elementary cam units

Optimum solution for tools that do not require the highest loads or work forces. ES-OT is a type of cam unit with the best price-performance ratio.

Dimensions

- Work surface: 50 – 410 mm

- Angle: 0 – 60° (5° step)

Technical properties

- Average service life: 1 million strokes

- Guaranteed service life: 250 000 strokes

- Average specific load: 1,1 kN/mm

- Cast material at least GJS400-15

Special cam units

Individual requirements often require a unique design. In addition to our flexible product portfolio, we are pleased to offer customised cam units. We rely on proven standard components and individual solutions.

There are nearly no limits to your individual requirements:

- Adapted work surface dimensions (also asymmetrical shapes)

- Adapted slide angles larger than standard up to 85° max.

- Adapted cam stroke

- Adapted outside cam unit dimensions

- Increased retraction force and workforce

- Casting design of work surface according to your requirements

- Mounting plate for upper sliding element

- Clearance for mechanisation equipment

- Clearance for projecting components, e.g. drawn edge