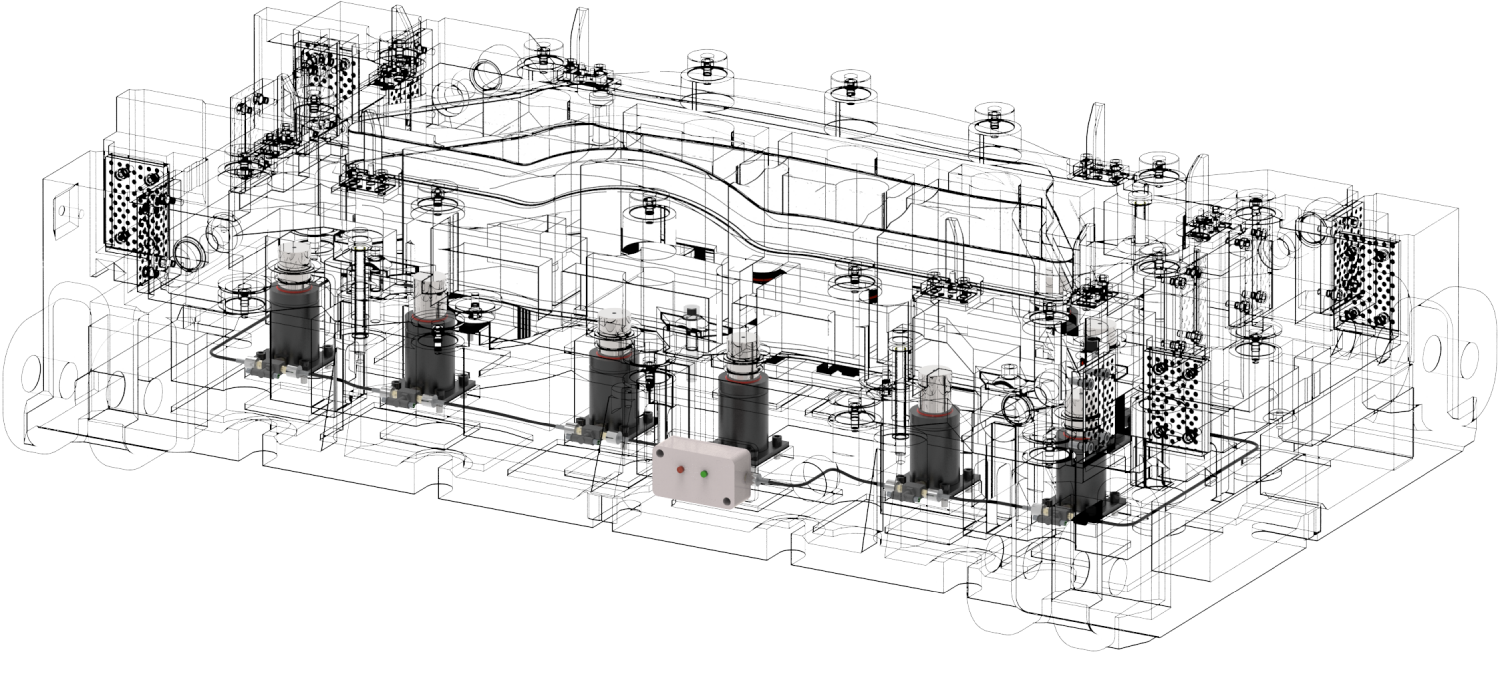

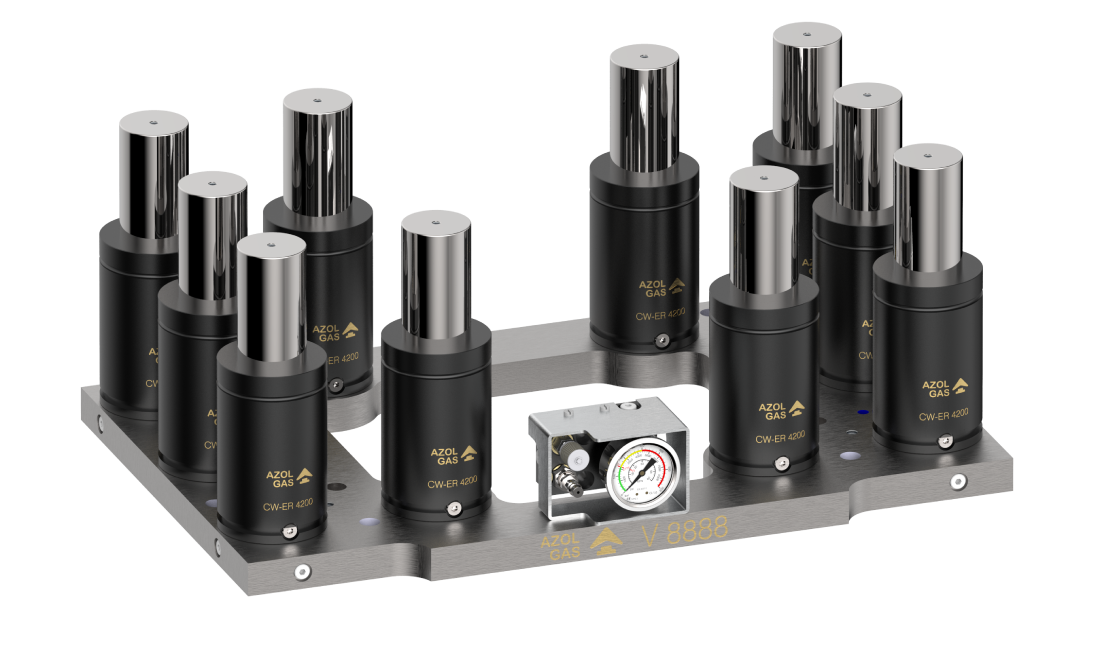

Nitrogen linked systems

The main purpose of using nitrogen systems in tools is to unify the pressure in individual gas springs. This ensures that the distribution of forces throughout the tool is uniform. A control panel located on the outside of the tool makes it possible to control and adjust the working pressure of the entire system.

Advantages of nitrogen systems:

- force balancing in different areas of the tool

- easy pressure change in springs

- pressure control via control panel

- monitoring and automating operations by means of sensors

Types of nitrogen systems

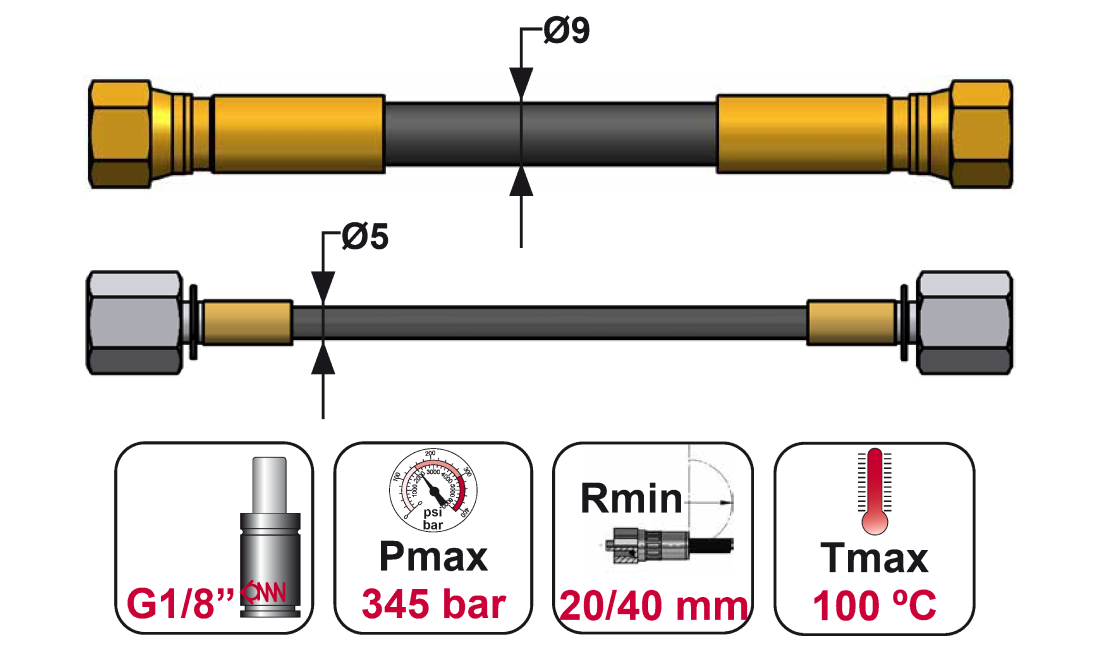

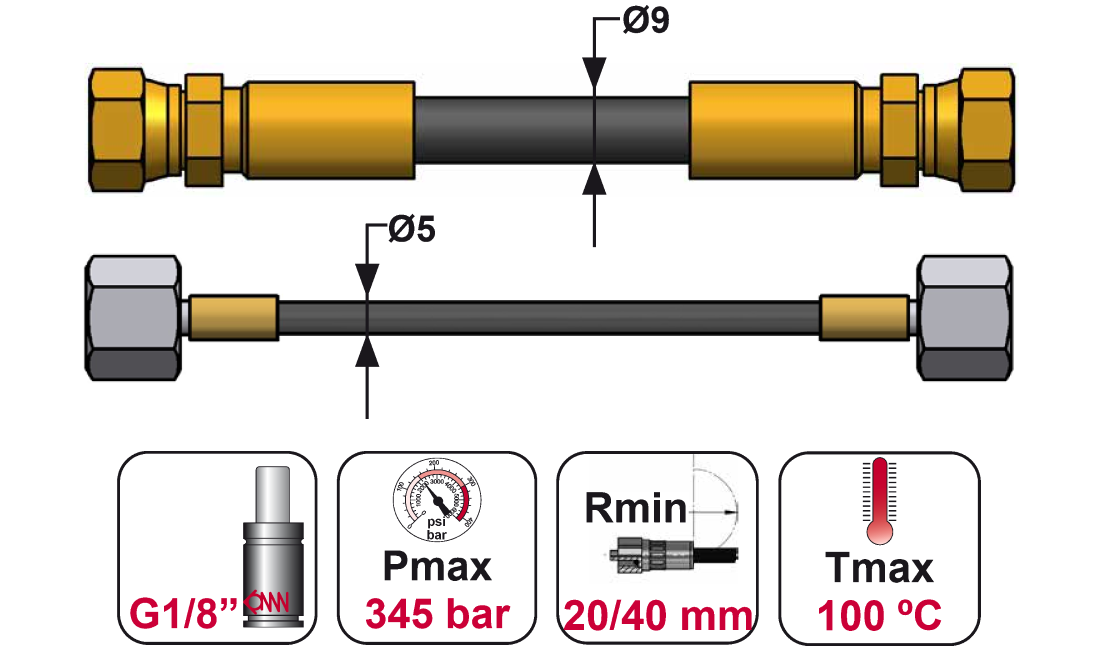

M12x1,5

Designed for high volume gas springs or ones with increased gas flow in the system

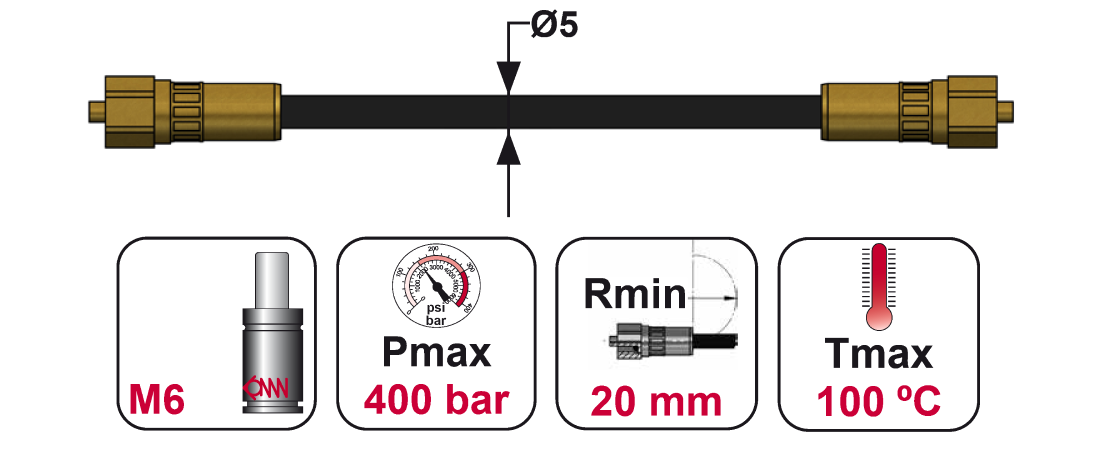

M8x1

The most compact, designed for gas springs with an M6 charging port

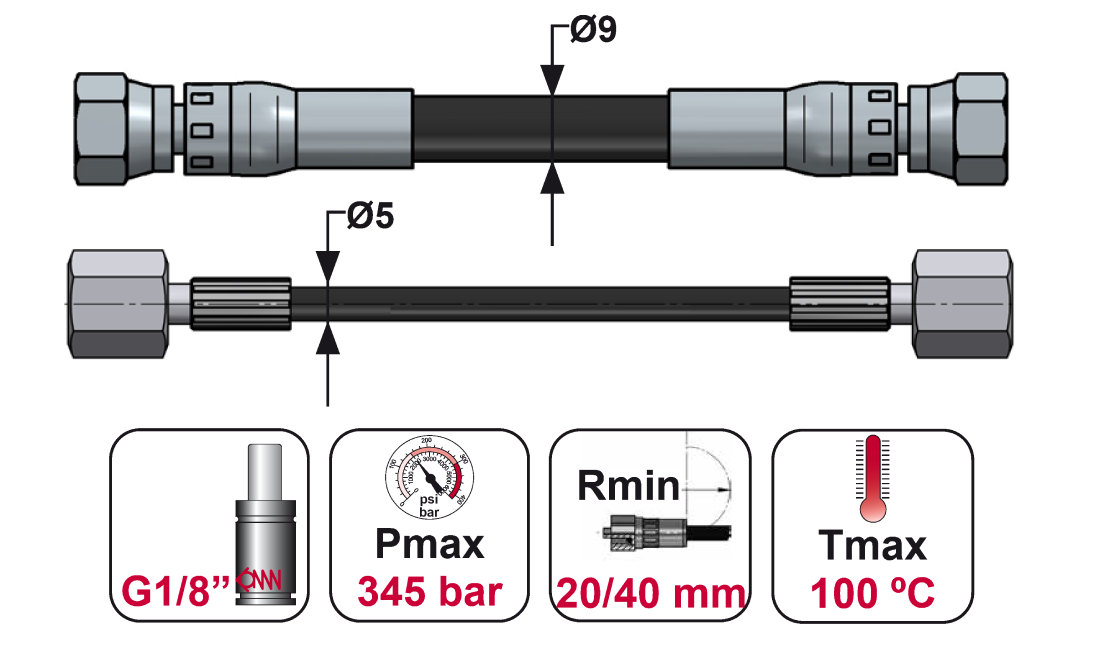

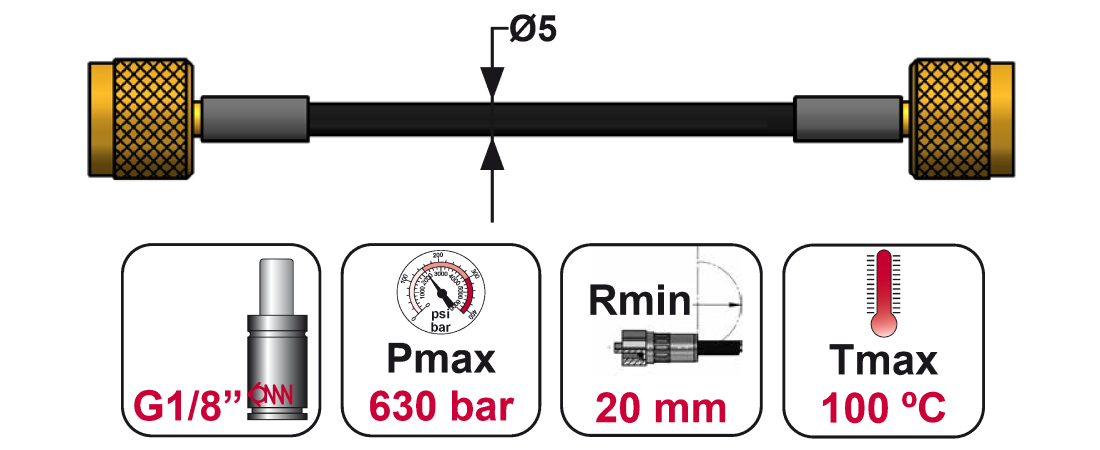

S12,65x1,5 (G1/8" Minimess)

The most popular automotive standard with an easy coupling system

7/16"

Designed for high volume gas springs or ones with increased gas flow in the system

9/16"

Recommmended for use in high-vibration applications

Manual - nitrogen systems

Find information on the parameters, installation, and service of nitrogen systems.

| Download the manual |

Online store

Check the availability and prices of AZOLGAS products in our online store.

| Go to the B2B store |